Cut to length Line Machine

Cut-to-Length Machines are designed for High-speed and accurate cutting of metal coils into precise sheet lengths. These machines ensure smooth Feeding, Straightening, and Cutting operations, providing exceptional Productivity and reduce material wastage.

Applications

Cut-to-Length Machines are widely used in Steel processing, Automotive, Construction, Electrical panels, Appliance manufacturing, and Sheet metal fabrication. They are ideal for processing materials like CR/HR steel, stainless steel, aluminum, and copper.

Advantages

- High cutting accuracy and consistent performance

- Reduced material wastage and better yield

- Suitable for a wide range of coil materials and thicknesses

- User-friendly controls with automatic length settings

- Low maintenance and robust construction for long service life

Slitting Line Machine

Slitting Line Machines are engineered for Precise and Efficient coil Slitting operations. These are designed to cut wide metal coils into multiple narrower strips with higher accuracy, with smooth edges. Our Slitting Lines ensure minimal downtime and maximum yield.

Applications

Slitting Line Machines are widely used in Steel processing, Automotive industries, Construction, Electrical panel manufacturing, and General Sheet metal Fabrication. They are suitable for processing CR/HR steel, stainless steel, galvanized coils, aluminum, and copper.

Advantages

- High-speed and precision slitting for various coil materials

- Consistent edge quality and burr-free cutting

- Heavy-duty build for continuous industrial operation

- Adjustable slitting width and recoiling options

GI/GP Slitting Line Machine

GI/GP Slitting Line Machine is designed to deliver high-accuracy slitting and superior edge quality for Galvanized Iron (GI) and Galvanized Plain (GP) coils. It ensures Smooth coil Feeding, Precise Slitting, and perfect Recoiling operations, Reduces material waste and Enhances Productivity.

Applications

GI/GP Slitting Line Machines are widely used in Steel Service Centers, Construction materials, Roofing sheet manufacturing, Appliance production, and Automotive components. They are ideal for slitting Galvanized coils, Cold-rolled steel, Stainless steel, and Aluminum into narrow strips for further processing.

Advantages

- High-speed and burr-free slitting for GI and GP coils

- Consistent edge finish and accurate coil width

- Strong structural design for long-term stability and reliability

- User-friendly operation with minimal setup time

The GI/GP Slitting Line Machine provides Durability, Precision, and Peak Performance, helping manufacturing industries achieve Higher Yield and Improved product quality.

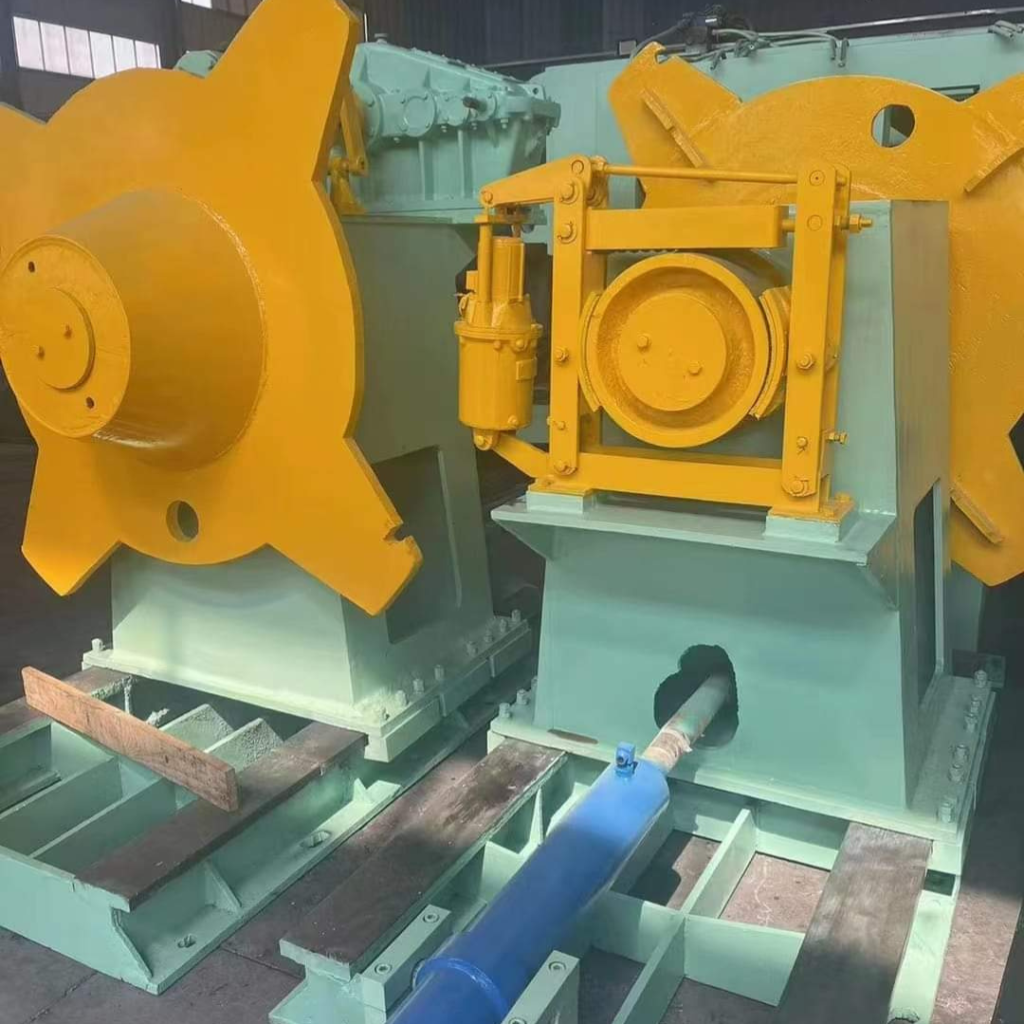

ERW & SS Tubemill

ERW (Electric Resistance Welded) and S.S. (Stainless Steel) Tube Mills are designed for the Production of High-quality Steel and Stainless Steel Tubes and Pipes with Exceptional Accuracy and Smooth Finish.

Applications

ERW & SS Tube Mills are extensively used in industries such as Construction, Automotive, Furniture, Structural engineering, Agricultural equipment, and General fabrication. They are ideal for producing Round, Square, and Rectangular tubes from materials like Mild steel, Stainless steel, and Galvanized steel.

Advantages

- High precision in tube diameter and wall thickness

- Smooth and uniform welding quality

- Easy operation with automated control systems

- High production speed and reduced downtime

- Low maintenance and long service life

Our ERW & SS Tube Mill’s Efficiency, Accuracy, , and Precision helps our customers to deliver tubes that meet International Quality Standards for a wide range of industrial applications.

Auto Blanking Line Machine

Auto Blanking Line is a fully Automatic Production System that converts metal coils (steel or aluminium) into flat stamped blanks. It includes an Uncoiler, Straightener/Leveler, Precision feed (Servo or Mechanical), a High-speed Blanking press or Rotary die, Scrap separation, and a Stacker/Conveyor for finished blanks. It is engineered for continuous, high-volume manufacturing with Precise length control and consistent part quality.

Applications

- Automotive: Panels, Brackets, Small structural parts

- Home appliances: Components for Washers, Ovens, Refrigerators

- Electrical parts: Transformer laminations, Contacts, Connectors

- HVAC parts, Clips and Mounting brackets

- Hardware: Washers, Spacers, Shims, Fittings

- Lighting housings and mounting components

Advantages

- High Productivity: Continuous coil feeding enables large-volume production.

- Accuracy & Repeatability: Precise feeding and tooling deliver consistent blanks.

- Lower Operating costs: Reduces Manual Labor and faster cycle times.

- Material Savings: Optimized coil use and precise feed reduces waste.

- Flexibility: fast tooling changeovers for different blank sizes and materials.

- Safe & Smooth Operation: Automatic Scrap Separation and enclosed press areas.

6-Hi Sheet Leveller

6-Hi Sheet Leveller is a High-precision Metal Processing Machine configured with 6 rolling levels (Work rolls, Intermediate rolls and Back-up rolls) that apply Controlled bending and Counter-bending to Flatten and Relieve RESIDUAL STRESS in metal sheet or coil fed materials.

Applications

- Cold-rolled and hot-rolled steel sheet processing for automotive, construction and infrastructure uses

- Stainless steel sheets for household appliances, architectural panels and decorative metalwork

- Aluminium and coated metal sheets requiring high flatness prior to further processing

- Pre-painted or decorative metal sheet lines where surface condition and flatness are critical

- Metal fabrication, stamping and assembly operations where flat, stress-free base material is required

Advantages

- High flatness & Consistency: The 6-Hi roll layout offers superior straightening capability especially for high strength or difficult materials.

- Stress Relief: Alternate bending/unbending removes internal stresses and reduces distortion, spring-back and rework downstream.

- Material & Process Versatility: Suitable for a broad range of material types, thicknesses and widths.

- Reduced Scrap & Improved Accuracy: Flat, stable sheets mean fewer rejects and better performance in downstream forming, welding, finishing.

- Higher Productivity & Automation Readiness: It supports Servo Roll Position Memory, Smooth roll motion, Minimal surface marking and high output.

4-Hi Sheet Leveller

4-Hi leveller combines a four-roller leveling arrangement (two work rolls between two larger backup rolls with an integrated plate/bending roll function). It flattens and relieves internal stresses (levelling mode). It can also prebend and roll plates into cylinders or multi-radius shapes (bending mode), eliminates extra handling and improves Workflow for Cut-to-length and Plate forming operations.

Applications

- Cut-to-length and Blanking lines for Steel, Stainless steel and Aluminium sheets.

- Pre-processing for Stamping, Deep-drawing, Welding and Assembly where flatness and stress relief are critical.

- Plate and fabrication shops requiring prebend + roll operations (cylinders, shells, cones).

- Processing of galvanized, pre-painted and high-strength materials where surface quality must be preserved.

Advantages

- Combined functions: Levels and bends/rolls in a single compact machine, reduces handling and cycle time.

- Pre-bend capability: Four-roll geometry allows pre-bending of Leading/trailing edges in the same pass for tight radii and small straight edges.

- High flatness & Repeatability: Backup rolls support smaller work rolls for consistent flatness across width and thickness ranges.

- Reduced scrap & Rework: Effective stress relief and accurate pre-bending lower spring-back and downstream rejects.

- Automation ready: Motorized roll settings, Servo control and Operator memory presets enable faster Changeovers and higher output.

Sheet Straightener Machine

Sheet Straightener Machine removes distortions- such as Coil-set, Edge-waviness, Cross-bow, Curl and Internal stress- from sheet or strip metal prior to downstream processing.

Applications

- Automotive sheet production- Flattening coil feed for Body panels, Brackets and Structural parts

- Home appliances / White goods- Preparing flat panels for Painting, Trimming and Assembly

- Construction and Metal furniture- producing flat sheets for Roofing, Cladding, Furniture, Frames

- Electronics and Precision hardware- Ultra-thin or high-flatness sheets for Enclosures, Housings and Frames

- Fabrication and Blanking lines- ensures accurate feed and material flatness for Stamping, Forming and Welding

Advantages

- Improved flatness & Precision: Corrects sheet distortions for better downstream processing accuracy.

- Internal Stress Relief: Releases residual stresses from prior processing, reduces spring-back and part warping.

- Material waste & Cost reduction: Flatter sheets ensure fewer rejects, less trimming and less rework.

- Versatility: Handles a wide range of materials (Steel, Stainless steel, Aluminium, Copper) and thicknesses.

- Increased Productivity & Automation ready: It offers motorized Roll setting, Servo control and Memory presets for fast changeover.

- Better Downstream Quality: Pre-straightened sheets enable smoother Forming, Welding and Finishing operations.

CNC/NC Bending (Press Brake) Machine

CNC/NC press brake(bending machine) is a computer-controlled forming machine used to BEND Sheet Metal and Plate to Precise Angles and Profiles. The machine features a Rigid frame, Punch & die Tooling, a Programmable RAM and Back-gauge(s) to execute Repeatable bends from simple flanges to complex multi-bend parts. CNC variants add Full programmability, Memory of Bend Sequences and closed-loop control for Higher accuracy; NC variants provide Numeric control with Simpler programming for Cost-sensitive applications.

Applications

- Sheet metal Fabrication: Enclosures, Panels, Brackets, Chassis and Housings.

- Automotive components and Assemblies needing Precise bend Repeatability.

- HVAC, Ductwork and Architectural metalwork—forming channels, Flanges and Trim.

- Electrical cabinets, Control panels and Rack mount fabrications.

- Job-shop and Contract manufacturing where quick Changeovers and consistent Output are required.

Advantages

- High precision & Repeatability: CNC control and Accurate back-gauges deliver Consistent Angles and Tight Tolerances.

- Faster setup & Reduced Scrap: Programmed bend sequences and tool presets SHORTENS Setup Time and Reduces Waste.

- Complex forming Capability: Multi-axis CNC Press brakes perform Compound and Sequential bends with ease.

- Lower Labor Dependence & Higher Output: Automation reduces Operator Load and increases Production speed.

- Flexibility: Available in a wide range of Tonnages, Bed lengths and Tooling options to suit Thin gauge to Heavy plate work.

Hydraulic Shearing Machine

Hydraulic Shearing Machine is a power-driven Cutting System that uses Hydraulic cylinders to apply a Shearing force between a Fixed Lower Blade and a Moving Upper Blade, which enables precise cutting of Sheet Metal or Plates. It offers an Adjustable blade gap, Hydraulic hold-down clamps, Back-gauge Positioning and Optional CNC/NC control to accurately cut a wide range of materials and thicknesses.

Applications

- Metal Fabrication: Cutting steel Sheets and Plates for Structural Components, Panels and Blanks.

- Automotive Manufacturing: Shearing body panels, Chassis parts and other components requiring clean edges.

- Construction & Infrastructure: Cutting beams, Roof panels and Plate material for Buildings, Bridges and Large-scale Fabrication.

- Appliance and Electronics Industries: Cutting Stainless Steel, Aluminium and Coated sheets for Enclosures, Housings, Precision parts.

- Job-shop / contract work: Versatile shears for multi-material and Varying Thickness Jobs where Changeover and Accuracy matters.

Advantages

- Precise & Clean Cutting: Hydraulic Force Controls and Adjusts blade settings, and make Burr-free edges with Minimal material distortion.

- Versatility in Material Handling & Thickness: Handles a broad range of Metals (Mild steel, Stainless steel, Aluminium) and thicknesses with Adjustable settings.

- Reduced Material Waste & Maintenance: Smooth Operation, Fewer Moving Parts, Improved Blade Life ensures Lower Scrap and Maintenance costs.

- Operator Safety & Control: Features such as hold-down Clamps, Back gauges, CNC/NC controls, Emergency stops and Light curtains enhance Safe, Efficient operation.

- Heavy-duty Capability: Hydraulic systems deliver consistent Large Shearing Force suitable for Heavy gauges and Demanding Applications.

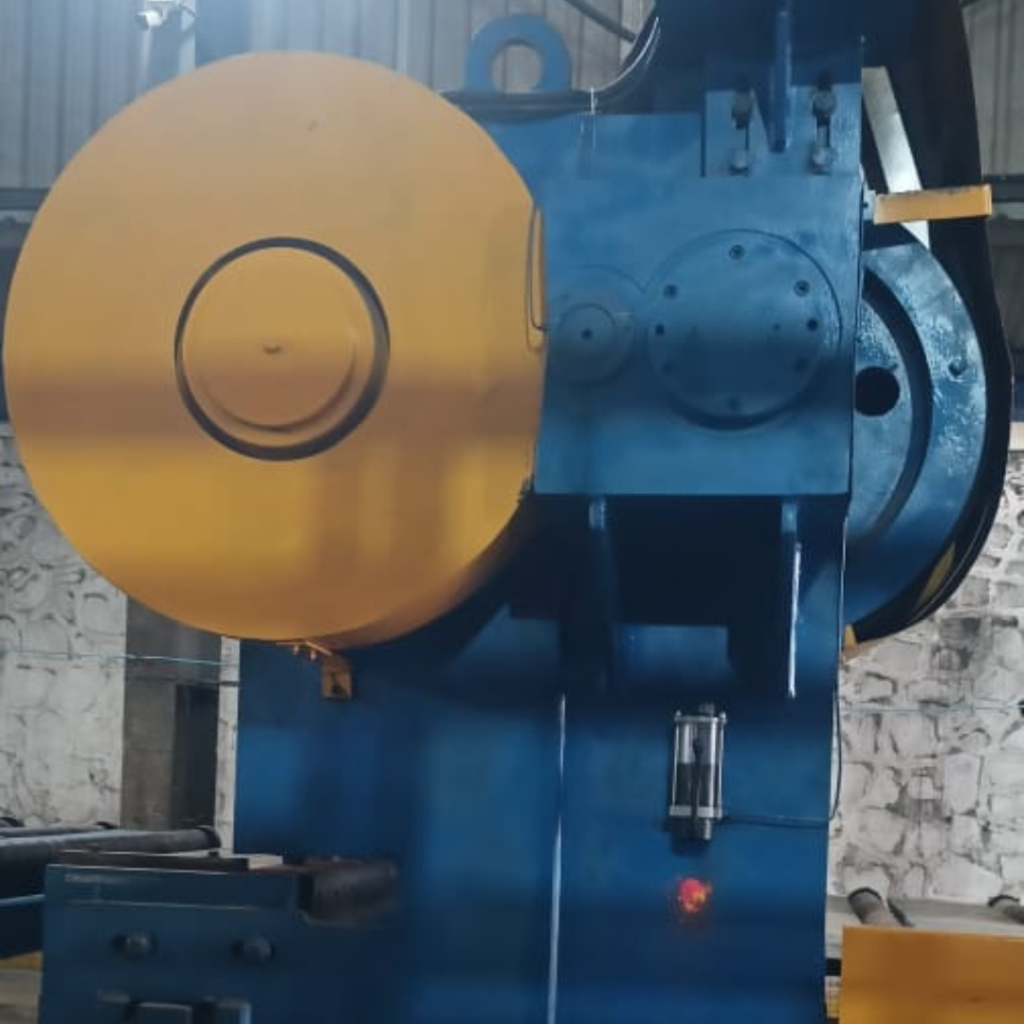

Mechanical Shearing Machine- (Overcrank/ Undercrank)

Mechanical Shearing Machine uses a Crank or Eccentric/ flywheel drive to move an upper blade linearly against a fixed lower blade to cut sheet and plate. In Overcrank machines the Crankshaft/ driving linkage is positioned above the frame for High capacity and Heavy Gauge Cutting; Undercrank machines place the Crankshaft below the bed for a more Compact, Economical layout Suitable for Medium and Lighter gauge work. Typical features include a rigid welded frame, spring or hydraulic hold-down pads, adjustable blade clearance, mechanical back-gauge (or optional NC/CNC gauge) and robust blade holders for repeatable, burr-controlled cuts.

Applications

- General Metal Fabrication- Cutting mild steel, Stainless steel and Aluminium sheets & Plates for Panels and Blanks.

- Structural and Construction Workshops – Cutting plate for Frames, Brackets and Gussets.

- Automotive and Components Manufacture – Trimming panels, Chassis parts and Brackets.

- Light Engineering, Ductwork and Appliance Manufacturing – Accurate sheet Cutting prior to Forming or Welding.

Advantages

- Economic & Efficient: Mechanical shearing machine delivers Fast Stroke Rates and Low cycle times for Cost-effective Production.

- Robust Cutting: Overcrank distribute Forces for Thicker plates; Undercrank gives compact Efficiency for thinner gauges.

- Easy Maintenance: Fewer Hydraulic Systems mean Easier Upkeep and Lower long-term Operating cost for many shops.

- Accurate & Repeatable Cuts: Proper Blade Clearance, hold-down systems and Back-gauges deliver Square, Burr-controlled Edges.

- Quick setup: Straightforward Tooling and Adjustments enable fast Changeovers for continuous shop Workflows.

Cantilever Type De-coiler

Cantilever Type De-coiler (uncoiler) is a Coil-handling Machine that supports and pays off metal coils from one side using a Cantilevered mandrel or arm allowing Quick, Safe loading and Unloading of coils without Threading an inner Arbor through the coil. Cantilever de-coilers come in Manual, Motorized and Hydraulic Mandrel versions and Typically include a Motor drive or Brake, Expandable mandrel or Cone, Coil cart/cradle options, hold-down devices and Electrical controls to coordinate Speed and Tension with downstream equipment.

Applications

- Roll-forming Lines – Feeding coils into Roll formers for Roofing, Purlins and Profile production.

- Slitting and Cut-to-Length Lines – Supplying material to Slitting, Straightening and Feed systems.

- Stamping and Blanking presses – Continuous coil Feed for high-volume Stamping operations.

- Coil-fed Laser/ Punch/ Press Feed Systems – where fast coil Changeover and Controlled payoff are required.

- General Metal Fabrication and Coil converting – Handling Steel, Stainless steel, Aluminium and Coated coils.

Advantages

- Fast & Safe coil Change: Side-loading and Coil cart options Reduce Handling Time and Risk of Coil damage.

- Flexible coil sizes: Expandable mandrels/ Hydraulic cones Accept a wide range of inner Diameters and Widths.

- Better Line Integration: Motorized/ CNC options enable coordinated Speed and Tension control for smooth Payoff.

- Space & Setup Savings: Compact Cantilever layouts and coil carts MINIMIZE Staging area and Speed setup.

- Different Variants: Cantilever type de-coilers comes in different categories such as Non-powered, Powered, Double-head or Hydraulic mandrel Models with various Capacities and Automation needs.

Manual Uncoiler (De-coiler)

Applications

- Roll forming and Profile Manufacturing

- Stamping, Shearing and Press lines

- Sheet metal Slitting and Cutting

- Light Fabrication shops, Prototyping and Low-volume Runs

Advantages

- Cost-effective: Lower upfront cost vs Motorized de-coilers.

- Easy operation: Simple manual controls for quick setup.

- Precise Tension Control: Reduces scrap and Improves part quality.

- Compact Footprint: Fits small production floors and is Portable.

- Flexible compatibility: Supports a range of coil Widths, Thicknesses and Inner diameters (check model specs).

Specifications:

| Parameter | Range |

|---|---|

| Coil Width | 70 – 800 mm (model dependent) |

| Coil Weight / Capacity | Up to 2,000 kg (model dependent) |

| Inner Diameter (I.D.) | Adjustable – standard mandrel type |

| Operation | Manual brake with tension control |

Why Choose Our Manual Uncoiler?

Our Manual De-coilers are perfect for businesses that want Dependable Coil Handling without high automation costs. Our de-coilers are built for Durability, Easy Service and Fast Installation – a Practical Solution for Workshops and Light-production lines.

Cone Type De-coiler

Applications

- Heavy Steel coil Handling for Shipbuilding and Structural Fabrication

- Roll forming and Cut-to-length lines for Thick Gauge Materials

- Continuous Production lines requiring High feed rates and Minimal Downtime

Advantages

- Superior coil Centering & Stability: Cone-mandrel design REDUCES Vibration and Misalignment.

- Continuous, high-capacity feed: Built for large coils and uninterrupted operation.

- Rugged durability: Heavy-duty construction for Long Service Life and Minimal Maintenance.

- Optimized for Thick Gauge and Large Diameter Coils: Handles what standard machines cannot.

Specifications:

| Parameter | Range |

|---|---|

| Coil width | Up to 1800 mm (Varies acc. to the Model) |

| Coil weight / capacity | Up to ~20 tons or more (Varies acc. to the Model) |

| Inner diameter (I. D.) | Adjustable – Depends on Mandrel Expansion System |

| Operation | Motor-driven Mandrel with brake/ Tension control |

Why Choose Our Cone Type De-coiler?

Our Cone Type De-coilers handles Large coils or Heavy gauge materials. It gives Unmatched Stability, Output and Reliability. It reduces the Downtime, maintains consistent Feed and protects your Material . Your investment in this machine pays dividends in the form of increased Output and improved Quality.

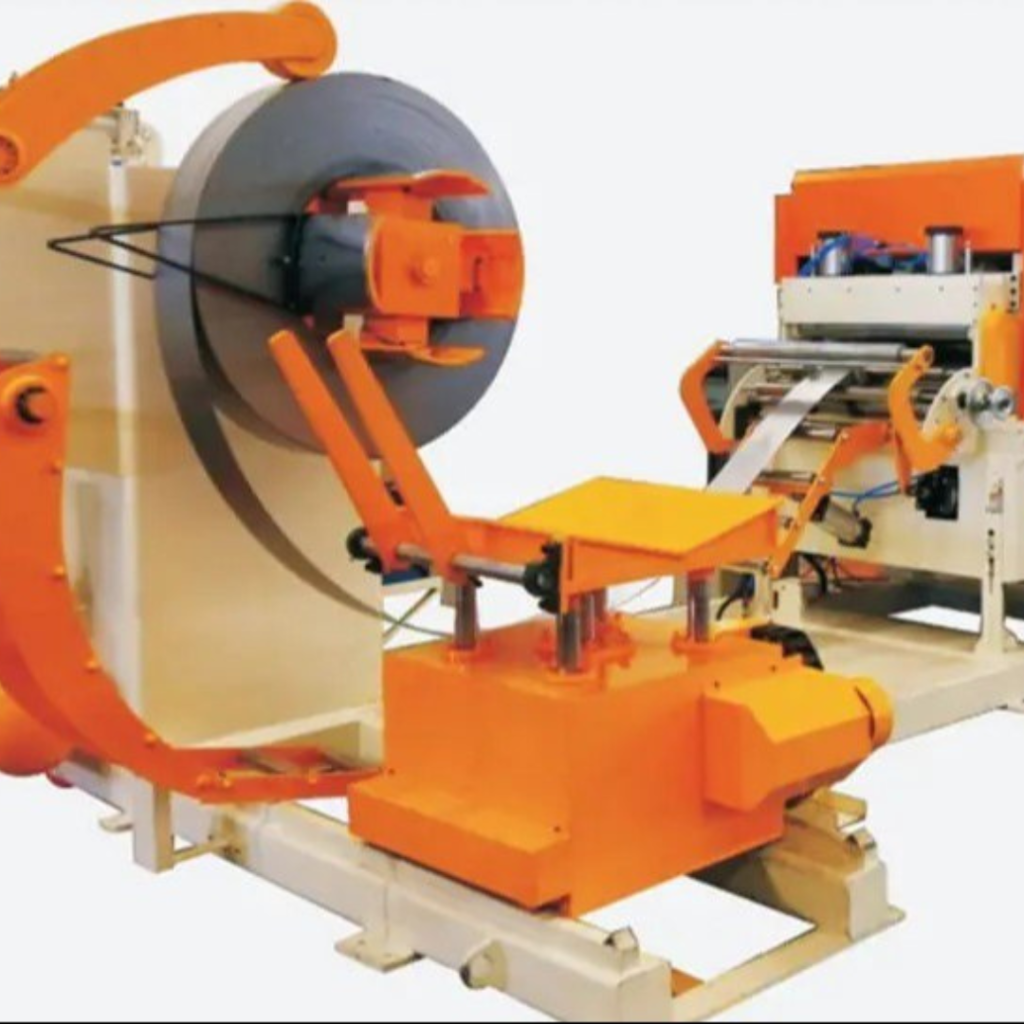

Un-coiler + Straightener + NC Servo Feeder (3-in-1)

Applications

- Progressive Stamping and Blanking presses for Automotive, Electrical and Appliance components.

- Roll forming, Slitting and Cut-to-length lines that require Continuous Flat Feed.

- Prototype and Production requiring Quick coil Changeovers and consistent Quality.

Advantages

- Precision feeding: NC servo control provides sub-millimetre Accuracy and Multi-pitch Feeding capability for complex part Geometries.

- Space-saving: It integrates De-coiler, Straightener and Feeder to save Floor space and reduces Capital Investment.

- Better Material Handling & Improved Quality: Straightening rollers reduce Springback and Edge defects, lowering Scrap rates.

- Smart control & Safety: PLC/servo Interfaces, Digital displays and Automated actions speed Setup and reduce operator Exposure.

Specifications:

| Parameter | Range |

|---|---|

| Strip thickness | 0.3 – 4.5 mm (Model Dependent) |

| Strip width | 20 – 1100 mm (Model Dependent) |

| Feeding accuracy | ≤ 0.15 – 0.5 mm (Servo controlled) |

| Feeding speed | Up to 20 m/min (Application dependent) |

Uncoiler (De-coiler) for Tubemill

Applications

- At Entry section of ERW/HFW tube mill lines for Steel Pipe Production.

- Coil feed for Roll forming, Slitting or Flattening systems integrated with Tube mills.

- Steel Tube Production in Construction, Automotive, Oil & Gas, Structural segments where coil handling is critical.

Advantages

- Reliable Strip Feed & Tension control: Ensures smooth Unwinding and Consistent feeding to AVOID Defects and reduced Scrap.

- Designed for Heavy-duty: Supports large coil Weights, various Widths and Thicknesses, and features Hydraulic/ expansion mandrel for flexible coil sizing.

- Minimimum Downtime: Options like Dual-mandrel structure or Cone design Enable fast coil Changeovers and near-continuous production.

- Versatile Integration: Compatible with Carbon steel, Stainless steel and Galvanized strips, and designed to integrate seamlessly with Tube mill Forming, Welding and Sizing systems.

Specifications:

| Parameter | Range |

|---|---|

| Max Coil Weight | Up to 10-20 tons (Model dependent) |

| Strip Width | 300 – 1500 mm (Tube Mill Entry) |

| Coil Inner Diameter (I.D.) | φ450-φ610 mm (with Expansion Mandrel) |

| Unwinding Mode | Passive or Motor-driven with Tension control |

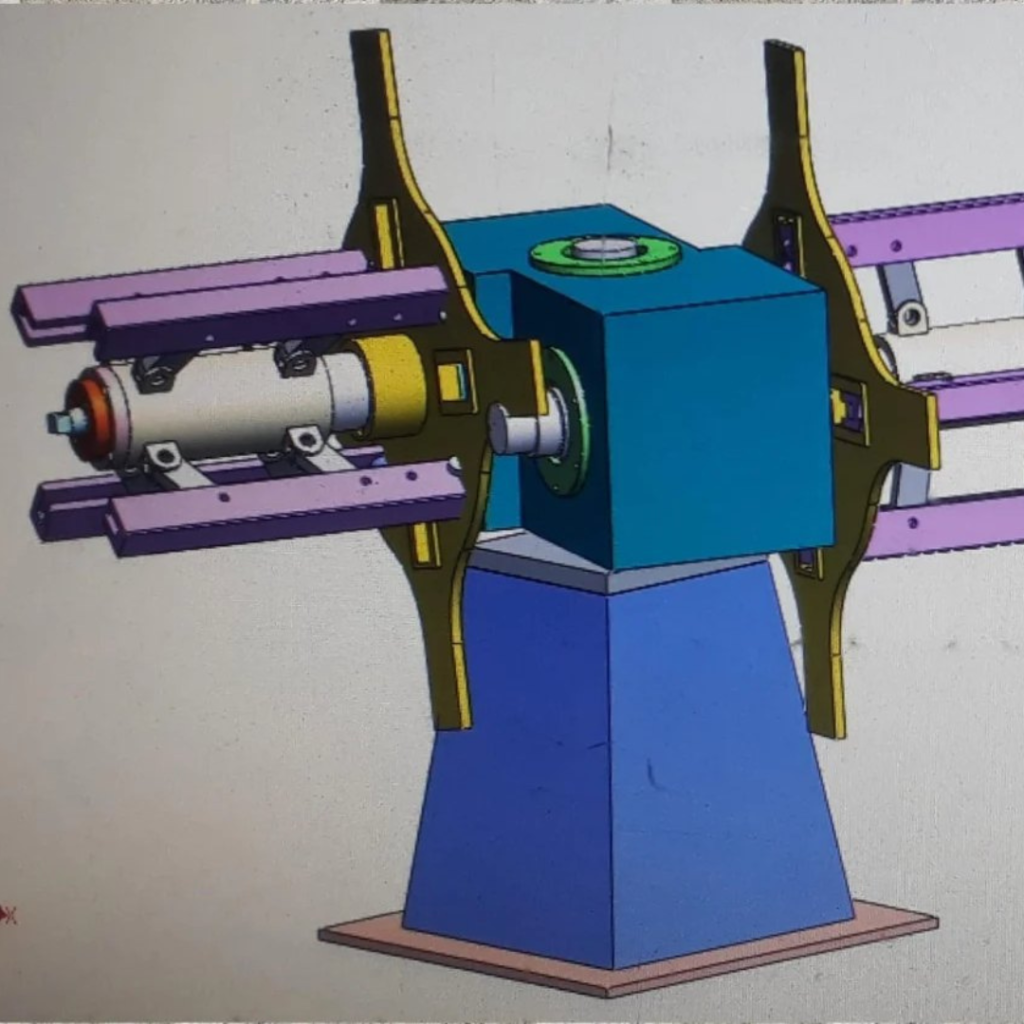

NC Zig- Zag Servo Feeder

Applications

- Stamping and Blanking Operations requiring Circular or Nested Blanks

- Press shops producing Washer, Gasket, and Round Component Blanks

- Integration with Mechanical, Hydraulic & Servo Press Lines

- Automotive, Electrical, Kitchenware & General Engineering Components

Advantages

- Reduced Material Waste: Zig-zag indexing significantly minimizes scrap, and maximizes coil utilization.

- High Feeding Accuracy: Servo-controlled motion ensures Precise Strip Positioning for consistent output.

- Optimum Production Speed: Fast indexing and quick step-adjustment ensure Continuous and Smooth workflows.

- Easy Programming: User-friendly NC control for setting Feed length, Stroke pattern, and Zig-zag parameters.

- Versatile Integration: Compatible with a wide range of Press Machines and Automation systems.

Specifications

| Parameter | Range |

|---|---|

| Material Width | Up to 600–1500 mm (Model dependent) |

| Material Thickness | 0.4 mm to 4.0 mm |

| Feed Accuracy | ±0.05 mm (Depends on material and speed) |

| Feed Speed | Up to 30 m/min (Varies by model) |

| Operation | Servo-driven with programmable NC controller |

| Compatible Press Type | Mechanical / Hydraulic / Servo Presses |

Why Choose Our NC Zig-zag Servo Feeder?

Manufacturers seeking to reduce coil costs, increase blanking efficiency, and improve production accuracy will benefit greatly from our NC Zig-zag Servo Feeder. It ensures optimal material usage, consistent output, and higher profitability — making it an essential upgrade for any sheet metal press-based production environment. Request Quote Download Spec Sheet (PDF)

Power Press with Servo Feeder

Applications

- Automotive sheet metal components manufacturing

- Electrical enclosures, switchgear, and appliance parts

- Precision blanking and punching operations

- High-volume stamping for metal fabrication units

- Press feeding for Cut-to-Length, Blanking & Progressive Die operations

Advantages

- High Feeding Accuracy: Servo-driven system delivers precise and repeatable material positioning.

- Increased Productivity: Rapid feeding cycles support high-speed stamping lines.

- Reduced Material Waste: Controlled feed lengths optimize coil utilization.

- Enhanced Safety & Automation: Automated feeding reduces manual handling.

- Seamless Integration: Compatible with mechanical, hydraulic, and high-speed presses.

Specifications

| Parameter | Range |

|---|---|

| Press Capacity | 25–250 Tons (Model dependent) |

| Feeding Width | 100–800 mm |

| Feeding Accuracy | ±0.05 mm to ±0.10 mm |

| Feed Length | Programmable as per requirement |

| Operation | Servo-motor driven with PLC control |

Why Should Sheet Metal Manufacturers Use It?

Manufacturers working with high-precision stamping, blanking, and progressive die applications benefit massively from a Power Press integrated with a Servo Feeder. It boosts productivity, improves part accuracy, and ensures consistent feeding—resulting in reduced downtime, higher throughput, and superior finished product quality. This combination is essential for scaling production while maintaining tight tolerances. Request Quote Download Spec Sheet (PDF)

H-Frame Power Press Machine

Applications

- Automotive component manufacturing

- Sheet metal stamping, punching & blanking operations

- Electrical panel and appliance fabrication

- Hardware and industrial parts production

- Forming, bending, and deep-drawing processes

Advantages

- High Structural Rigidity: H-frame design eliminates vibration and improves tool life.

- Consistent Accuracy: Ensures precise forming results in high-volume production.

- Heavy-Duty Build: Designed for demanding and continuous industrial usage.

- Improved Safety: Equipped with modern safety guards and control systems.

- Superior Force Distribution: Uniform load transfer increases reliability and output.

Specifications

| Parameter | Range |

|---|---|

| Capacity | 25 to 300 Tons (Model-dependent) |

| Stroke Length | Adjustable — depends on application |

| Bed Size | Customizable as per tooling requirement |

| Operation | Mechanical / Pneumatic clutch & brake system |

| Frame Type | High-strength welded H-Frame |

Why choose H-Frame Power Press Machine?

Manufacturers across the sheet metal industries can choose Mantra Machineries’ H-Frame Power Press for its unmatched strength, precision, and long-term reliability. It enhances production output, reduces maintenance needs, and supports demanding operations like deep drawing and heavy forming. This machine ensures stable, accurate, and cost-efficient manufacturing—making it an ideal investment for modern fabrication setups. Request a Quote Download Spec Sheet (PDF)

C-Frame Power Press Machine

Applications

- Sheet metal stamping, punching and blanking for automotive, appliance, and general metal fabrication parts

- Bending, forming and shaping of mild steel or light/high ductility metal sheets

- Small to medium batch production runs where quick die changes and flexible layout are required

- Fabrication of brackets, enclosures, metal housings, components for electronics, construction and light engineering

Advantages

- Space-saving design: The open C-frame occupies less floor space than larger straight-side or H-frame presses, ideal for smaller workshops or constrained production areas.

- Easy access & rapid setup: Open front and side access makes loading materials, setting dies, and removing finished parts easier — reducing downtime and increasing productivity.

- Versatility: Suitable for punching, blanking, bending, forming — with flexibility to handle different dies and jobs, which helps when manufacturing a variety of sheet-metal parts.

- Cost-effective: Typically more affordable and easier to maintain than larger, more rigid press types, making it ideal for small to medium workshops or jobs with moderate tonnage requirements.

- Suitable for light-to-medium duty: Provides sufficient force and accuracy for many sheet-metal tasks without the high costs and footprint of heavy-duty presses.

Specifications

| Parameter | Range |

|---|---|

| Capacity | 5 – 250 Tons |

| Bed Area (L × B) | 350 × 300 mm – 1200 × 800 mm (approx.) |

| Slide / Ram & Bed Material | Heavy-duty cast iron or alloy steel |

| Drive / Clutch System | Mechanical (geared or ungeared) |

Why sheet-metal machinery manufacturers should use it?

For sheet-metal machinery shops — dealing with cut-to-length lines, slitting, forming, shearing, and fabricating components — the C-Frame Power Press offers a cost-effective, space-efficient and flexible solution. It handles a wide variety of tasks (punching, blanking, bending, forming) with easy die changes and minimal setup time. Its balance of versatility, affordability and reliable performance makes it ideal for small-to-medium production runs, prototyping, and diversified metal part manufacturing — helping you maximize output without excessive investment.

Component leveller machine

Applications

- Flattening and stress relief of sheet metal, strips, and cut components before forming or fabrication.

- Preparation of blanks for stamping, laser cutting, bending, and welding.

- Precision metal parts production for automotive, electrical panels, appliances, and structural components.

- Leveling metal parts for CNC punching and press automation lines.

Advantages

- Superior flatness & quality: Precisely removes internal stresses and deformation, boosting consistency and surface quality.

- Improved downstream performance: Reduces rejects, rework, and cycle times in forming, welding, and machining.

- Versatile material handling: Suitable for mild steel, stainless steel, aluminium, and other alloys across thickness ranges.

- Enhanced productivity: Automated leveling reduces manual preparation and increases throughput.

- Consistent results: Repeatable flattening and stress relief lead to predictable quality output.

Specifications:

| Parameter | Range / Typical Value |

|---|---|

| Material Type | Mild Steel, SS, Aluminium, Coated Sheets |

| Width Capacity | Up to ~1500 mm |

| Thickness Range | 0.5 – 16 mm |

| Straightening Rolls | 11 – 31 rolls or more |

| Drive Type | Electric / Gear Drive |

| Control | Manual, Semi-Automatic or Fully Automatic Control Panel |

Why Sheet Metal Machinery Manufacturers Should Use It?

For manufacturers working with Cut-to-Length Machines, Slitting Lines, Press Feeding Systems, CNC or Power Press operations, a Component Leveler Machine is essential. By delivering flat, stress-free material and parts, it significantly improves dimensional accuracy and reduces defects in forming, welding, and assembly. This enhances overall production efficiency, reduces waste and rework, and helps achieve higher quality standards in sheet metal fabrication processes — making it a valuable addition to modern metalworking lines.

Semi Auto Stacker

Applications

- Stacking sheet metal blanks after cutting, punching or slitting operations

- Loading and unloading pallets in warehouses and production floors

- Transporting heavy parts between presses, shears and storage racks

- Supporting assembly line staging of components and finished goods

- General material handling in workshops, fabrication shops and logistic areas

Advantages

- Reduced manual effort: Semi-auto operation reduces operator fatigue and boosts efficiency.

- Cost-effective: Lower cost than full automation while improving productivity.

- Compact and agile: Designed for narrow aisles and tight spaces.

- Improved safety: Stable handling minimizes load shifts and work-related injuries.

- Versatile use: Works with a wide range of loads and production layouts.

Specifications:

| Parameter | Range / Typical Values |

|---|---|

| Load Capacity | 500 kg – 2,000 kg |

| Lifting Height | Up to ~3,000 mm |

| Operation | Semi-automatic hydraulic lifting with manual travel |

| Frame | Heavy-duty welded steel construction |

| Wheels | PU / nylon wheels for smooth maneuvering |

Why Sheet Metal Manufacturers Should Use It?

Manufacturers dealing with cut-to-length machines, slitting lines, presses, and fabrication lines benefit from a Semi Auto Stacker by streamlining part stacking and material movement, reducing manual labor and workplace injuries, and improving workflow continuity. Its compact, semi-powered design enhances operational efficiency in both small shops and larger industrial facilities.

Auto Pusher Stacker

Applications

- Pushing and stacking sheet metal parts after cutting, slitting or blanking operations.

- Integration with conveyors and roll forming lines for automated stack accumulation.

- Layered stacking of panels, blanks, and cut components for packaging or next-stage processing.

- Warehouse pallet stacking and preparation for dispatch.

Advantages

- Automated stacking: Eliminates repetitive manual stacking and improves throughput.

- Consistent alignment: Ensures neat stacks and reduced rework.

- Integration ready: Works with conveyors, conveyor stackers, and robotic feed lines.

- Enhanced safety: Minimizes manual handling risks and operator fatigue.

- Boosted productivity: Supports continuous stacking in high-speed processes.

Specifications:

| Parameter | Range / Typical Values |

|---|---|

| Stacking Load Capacity | Up to ~1000 kg |

| Stacking Speed | Depending on configuration and line speed |

| Control | PLC / HMI-based automatic sequence control |

| Integration | Conveyor / Roll forming / Press feed lines |

| Safety Features | Emergency stops, sensors for alignment and obstruction detection |

Why Sheet Metal Manufacturers Should Use It?

Manufacturers using cut-to-length machines, slitting lines, roll forming, presses, or automated fabrication lines should consider an Auto Pusher Stacker to streamline stacking operations, reduce manual intervention, and achieve higher consistency in stacking profiles. It enhances workflow continuity, reduces downtime between cycles, and improves overall operator safety in heavy-duty production environments.

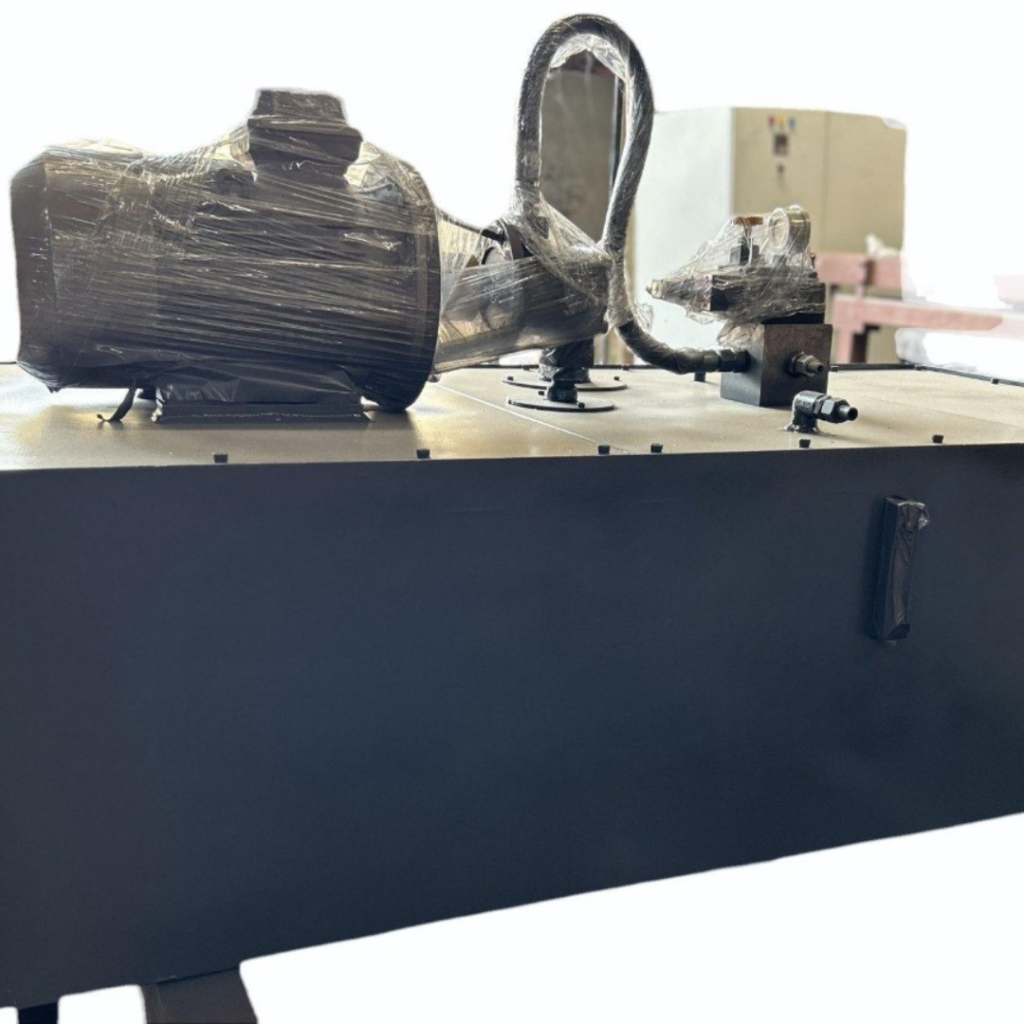

Industrial Hydraulic Power Pack

Applications

- Powering hydraulic presses, bending and forming machines in sheet metal fabrication plants.

- Operating shearing machines, levelers and CNC equipment requiring consistent hydraulic force.

- Material handling systems like pallet lifts and hydraulic conveyors.

- Automation and industrial production lines needing precise speed and pressure control.

- Integration with presses, jacks, lifts and other hydraulic actuators in manufacturing units.

Advantages

- High power density: Delivers strong force in a compact design.

- Precise control: Smooth, adjustable speed and pressure output for accurate performance.

- Reliable operation: Designed for continuous duty under heavy loads.

- Low maintenance: Robust construction with integrated filtration minimizes downtime.

- Versatile integration: Compatible with a wide range of hydraulic equipment.

Specifications:

| Parameter | Range / Typical Values |

|---|---|

| Motor Power | 1.0 – 100 HP |

| Tank Capacity | 50 – 1500 Liters |

| Pump Flow Rate | 1 – 200 LPM |

| Operating Pressure | Up to 350 Bar |

| Control | PLC/HMI or Manual Valve Control |